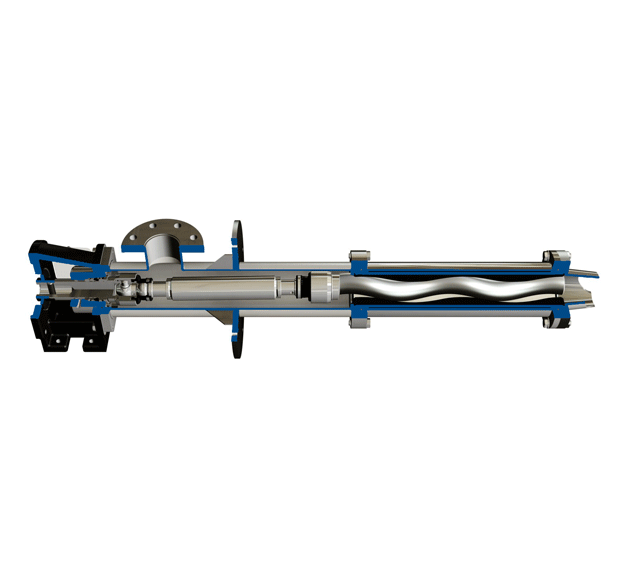

Vertical Progressive Cavity Pump

Max. Flow:

110m³/hr

Max. Head:

120m

Max. Temp:

150°C

Material:

Metal

Our Hopper Pump is a specialised solution designed to handle substances with high viscosities and significant solids content, surpassing the capabilities of standard Progressive Cavity Pumps in processing challenging liquids. Featuring Auger Feed Screws, this EHEDG-certified Hopper Pump efficiently handles industrial and food-grade liquids. With options including close-coupled or bearing housing supported variations, this pump delivers increased versatility. Additionally, the standard rectangular shape of the hoppers is customisable to suit your specific installation requirements.

Typical applications for our Hopper Pump:

| Materials | Stainless Steel AISI 316L, Carbon Steel |

| Max Capacity | 110m³/hr |

| Max Pressure | 480m |

| Self Priming | No |

| Solids Concentration | 18% |

| Max Temperature | 150ºC |

Tell us what you need to pump and we will supply the solution!

Leave your contact number and our team will be in touch within 30 minutes!

If you have further questions, our Pump Specialists will have the answer. Please don't hesitate to get in touch:

Tel:

+971 4 2352717

Email:

sales@tapflogulf.com

Open hours between:

08:30-17:00 - Mon-Fri

Notifications