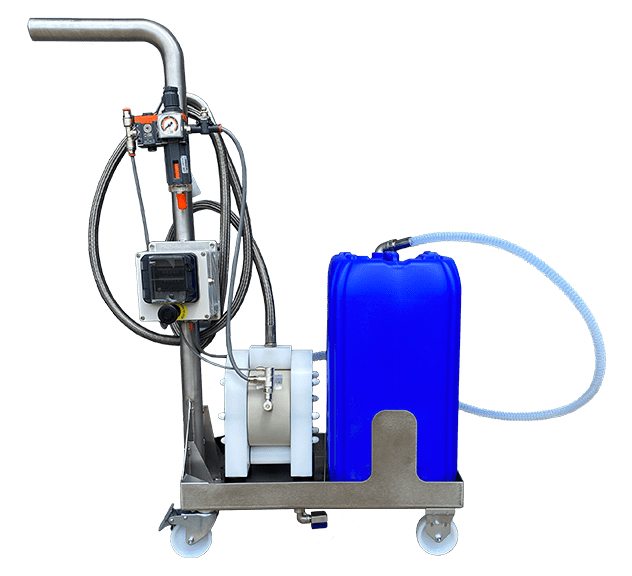

Mobile Decanting Unit

Our Mobile Decanting Unit (MDU) is an integrated system comprising a Tapflo Air Operated Diaphragm Pump (AODD), Pneumatic Batcher, PoD Valve and a purpose-built trolley. Versatile and convenient, the MDU is expertly crafted to handle chemical containers of 20L, 25L or 205L with ease. Our Mobile Decanting Unit features a discharge lance equipped with a PoD Valve and adjustable swan neck, enabling precise dispensing directly into required points without the need for manual handling of hazardous chemical buckets. The Pneumatic Batcher, which is a fully pneumatic predetermining counter system, accurately registers pump strokes via the air exhaust of an AODD. It halts the pump once the pre-set number of strokes is reached, providing precise and controlled dispensing for various applications.

Typical Chemical tasks for our Mobile Decanting Unit:

- Dispensing

- Batching

MDU-20 Mobile Decanting Unit:

- A safe and efficient solution for handling chemicals in the process. It eliminates the risks associated with carrying open containers of chemicals and ensures precise control over the amount of dispensed chemicals, preventing over-dosing. The unit features a PoD valve to prevent drips, improving accuracy by minimising the wet leg

- Designed for ease of use, the MDU-20 is fully pneumatic, making it easy to manoeuvre and self-braking when in a vertical position. It can be adjusted to suit differing chemical container neck positions and its stainless-steel trolley construction ensures durability and broad media compatibility. The integral hose stowage and simple operation further enhance its practicality

MDU-200 Mobile Decanting System:

- Like the MDU-20, it removes the risks associated with carrying open containers of chemicals and precisely controls the amount of dispensed chemicals to prevent over-dosing

- This mobile unit includes a shepherd’s crook with an integral NRV, ensuring accuracy and minimising drips during dispensing. Its fully manoeuvrable design with locking front wheels allows for easy mobility. The MDU-200 is fully pneumatic and comes with integral hose stowage, offering simple operation and broad media compatibility

- The system’s integral refilling capability and removable top-plate and front legs enable easy container replacement. With its stainless-steel trolley construction, the MDU-200 ensures durability and reliability

Both units are ideal for positioning next to the dosing point, eliminating the need for long chemical lines and streamlining the chemical handling process.

| Max Capacity | 50 l/min |

| Rated Capacity at 4 Bar | 30 l/min |

MDU-20 System: designed for 20L and 25L containers

MDU-200 System: designed for 205L drums

- Pneumatic Batch Controller

- TX50 PTT AODD

Both systems feature the following key components:

- TPUK-BP Pneumatic Batch Controller

- TX50 PTT Air-Operated Diaphragm Pump

- Pump Speed Control Blocking Needle Valve

- Air Filter & Pressure Regulator with Gauge

- Stroke Sensitivity Adjustment Screw

- Discharge Hose with PoD valve and Adjustable Swan Neck