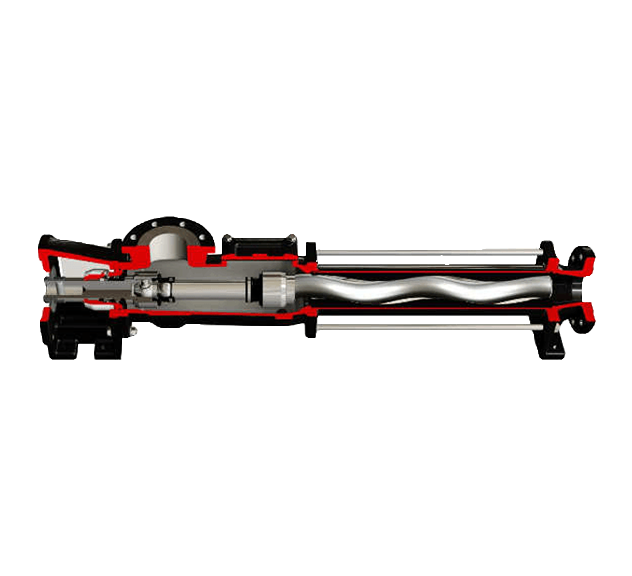

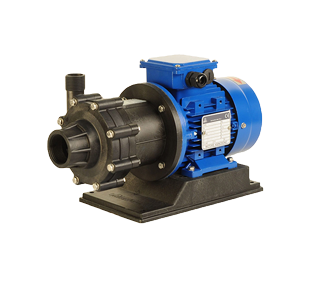

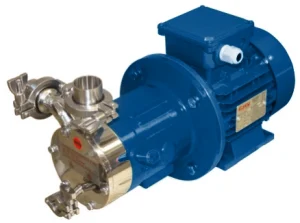

Mag Drive Alloy Regenerative Turbine Pump

Our Mag Drive Alloy Regenerative Turbine Pump is a precision-engineered Centrifugal Turbine Pump designed for low flow and high head applications. Featuring robust construction features, these pumps offer a reliable solution with zero leakages even in extreme working conditions. The elimination of mechanical seals or packing glands ensures an environmentally friendly operation, safeguarding workers and the surroundings.

Typical applications for the Mag Drive Alloy Regenerative Turbine Pump:

- Pumping dangerous and radioactive liquids

- Transfer of solvents, acids, alkalis, refrigerants

- Heat transfer oil and explosive fluids

- Pilot plants

- Mechanical seal flushing

- Chemical processing

- Hydrocarbon processing/refining

- Biofuels

- Pulp & Paper

- Pharmaceutical, Biochemical Solutions

- Maintains head and flow for an extended running period

- The multi-vanes self-balancing impeller eliminates thrust loads, allowing the pump to be started with a completely open discharge valve

- Suitable for thin, non-lubricating media with a very low Net Positive Suction Head (NPSH) value

- Reversible rotation

- Can be used as a mixer for liquids with different characteristics

- Fully encapsulated external magnet

- Bronze rub ring as standard

- Coupling Housing with removable Feet for smaller models

- Heavy-duty machined pressure parts

- Low maintenance costs

- High MTBF (Mean Time Between Failure)

- High-torque cobalt samarium magnets

- ATEX compliance

| Materials | Stainless Steel AISI 316L, Incoloy 825, Alloy 20, Hastelloy C-276, Duplex/Super Duplex, Titanium & Others on request |

| Max Capacity | Up to 16m³/hr @ 50 Hz & up to 17m³/hr @ 60 Hz |

| Max Pressure | 200m @ 50 Hz & 240m @ 60 Hz |

| Self Priming | Yes, when fitted with a non-return valve |

| Max Temperature | 315ºC |

- Close Coupled for Hygienic Applications

- Special Execution for High Temperature Applications

- Flanged ports ISO/ANSI

- Tri-clamp ports

- High-temperature design

- Low-temperature design

- High-pressure design

- Special polished finishing

- Jacketed coupling housing

- Jacketed end cover

- Thermowell