Diaphragm Pump Pneumatic Level Controller

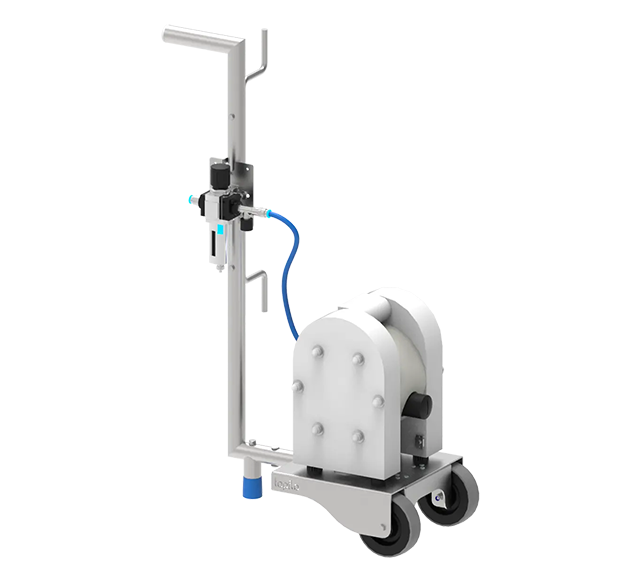

Our Diaphragm Pump Pneumatic Level Controller is a solution that exclusively uses pneumatic components. Designed for easy installation in sumps, tanks or containers, this controller starts and stops the pump at specific liquid levels. For automatic start/stop, the TPUK-LA variant can be used. Additionally, it can be manually controlled using the TPUK-LM variant. The compact panel, measuring 200 x 200 x 130mm, is compatible with all Tapflo Diaphragm Pumps and is available in ABS Plastic (IP55 or 65) or Stainless Steel AISI 316 (IP44).

Typical industries for our Diaphragm Pump Pneumatic Level Controller:

- Water Treatment

- Food & Beverage

- Pharmaceutical

TPUK-LA:

- Automatic evacuating/filling of vessels or sumps

- Uses low-pressure air through dip tubes to accurately detect liquid levels

- Configurable in ‘filling’ or ’emptying’ modes

- Precise level control, starting or stopping the pump as required

- Highly accurate, sensing levels within a few millimetres

TPUK-LM:

- Enables manual evacuating/filling of vessels or sumps

- Manually starts the AODD pump for filling or emptying

- Automatically stops the pump when the liquid surface is detected at the dip tube

| Materials | ABS Plastic (IP55 or 65), Stainless Steel AISI 316 (IP44) |

| Ambient Temperature | -5°C to 40°C |

| Air Pressure, Bar (G) | 30 – 70m |

| Pilot Output Flow Rate @ 60m with P = 1 | 120 NI/min |

| Air Consumption (system only) | 2 l/min (average) |

Our TPUK-LA and TPUK- LM Pneumatic Level Controllers need either a Blocking Needle Valve as preferred, or a Blocking Valve, sized to suit the pump. As an optional extra, the TPUK-LM can be supplied with a TPUK-SSR Remote Start/Stop Controller for enhanced operational control and efficiency.

TPUK-LA:

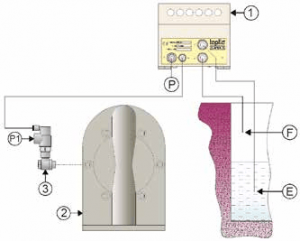

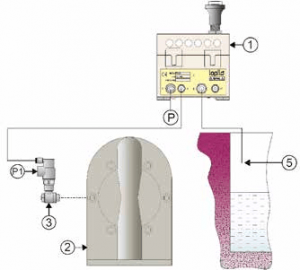

Our Automatic Pneumatic Level Controller is an automated system for evacuating or filling vessels and sumps. The Level Controller uses low-pressure air through dip tubes to detect liquid levels, offering precise control within a few millimetres. Operating in ‘filling’ or ’emptying’ modes, the system uses hoses placed at low and high levels in the sump. When liquid nears the high-level hose, the pump starts or stops, ensuring the desired liquid level is accurately maintained.

- 1: TPUK-LA Level Controller

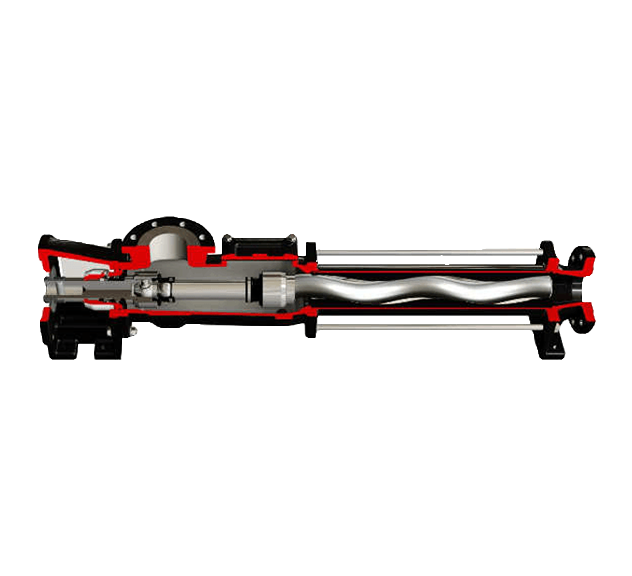

- 2: AODD Pump

- 3: Blocking Needle Valve

- P: Air Supply to the Level Controller

- P1: Air Supply to the Pump

- F: Hose placed at a higher level

- E: Hose placed at a lower level

TPUK-LM:

Our TPUK-LM is a system that is initiated manually, activating the AODD for either emptying or filling the vessel or sump. The pump automatically stops operation upon detecting the liquid surface at the dip tube.

- 1: TPUK-LM Level Controller

- 2: AODD Pump

- 3: Blocking Needle Valve

- 5: Dip Tube (example shows filling)

- P: Air Supply to the Level Controller

- P1: Air Supply to the Pump