Eccentric Disc Pump

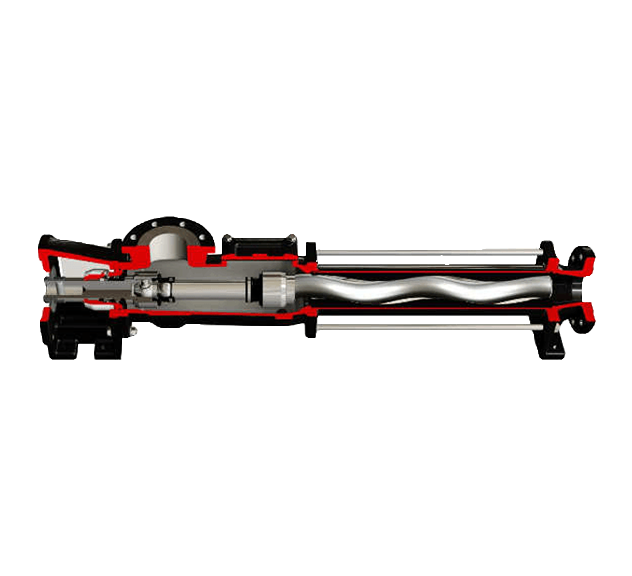

The Eccentric Disc Pump operation is characterised by a disc eccentrically rotating within a cylindrical pumping body. As the disc moves within the body, two distinct alternating chambers are created, which form a vacuum at the inlet area and a compression effect at the pump’s discharge.

This alternating action is repeated twice per rotation of the disc, once for the inner and once for the outer pumping chamber, as displayed in the above image.

As the chambers are rotating in a pair, 180º apart, suction compression and discharge pressure are generated in unison. This enables a constant flow rate and discharge pressure during operation. This unique operating principle provides a reliable alternative to Gear & Lobe Pump technologies which suffer when pumping non-lubricating fluids.

Furthermore, as there is no internal wear interference over time, volumetric efficiency is retained over time. Constant wear within Gear & Lobe Pumps also means higher product shear due to an internal slip; this is avoided in Eccentric Disc Pumps, which makes them ideally suited for low viscosity products susceptible to shearing, such as yoghurts.

Eccentric Disc Pumps are ideal for shear-sensitive products. The following applications are a few examples of where these pumps can be useful:

Food Industry – Yoghurts, cream, chocolate, chocolate mousse, dough, syrup

Cosmetics & Pharmaceutical Industries – Ointments, lotions, toothpaste, lipstick, mascara

Chemical Industry – Solvents, Polymers, Acids

Industrial – Oil, Fuel, Paint, Glue

Eccentric Disc Pumps are an efficient alternative to Lobe Pumps – don’t slip with low viscosity fluids

Better for shear-sensitive & low viscosity fluids

Strong Compression & Vacuum Capabilities – Excellent for line stripping

Capable of precise dosing & accurate volumetric metering

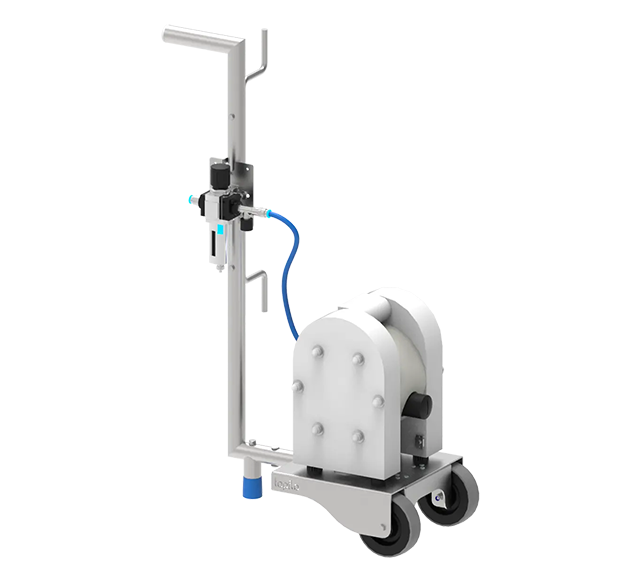

Front Pull-Out Seal Replacement

Dry running

Reversible

Reduced maintenance time thanks to a design which enables the seal from the front of the pump to be changed without uncoupling the gear motor and piping

Optional Integrated Double By-Pass & Heating Jacket

Temperatures up to 250˚C

Differential pressures up to 100 meters

FDA Approved & ATEX Rated

Capacity Range: Up to 96 m³/hr

Pressure Range: Up to 100 meters

Temperature Range: -10ºC to +250ºC

Speed Range: Up to 1000 rpm

Connections: Flanged, Clamp, SMS, Macon, RJT, CAM Lock, DIN, Threaded, Hose Tailed

By-Pass: Integrated Double By-Pass Optional

Heating Jacket: Optional

Pump Body, Cover, Foot, By-Pass & Shaft:

Ductile Iron

Steel

Stainless Steel AISI 316L

Stainless Cast Iron

Piston:

Ductile Iron

JumpInox

Stainless Cast Iron

Cylinder:

Ductile Iron

Stainless Steel AISI 316L

Steel

Bearings:

Carbon

Bronze

Ductile Iron

PEEK

Seals (DIN 24 960 / EN 12 756):

FKM

PTFE

FEP/FKM

EPDM

NBR

To be confirmed