High-Pressure Dosing Diaphragm Pump

Tapflo Gulf is proud to be the exclusive UAE Partner of Doseuro, a leading Italian manufacturer of the highest-quality Metering Pump Solutions.

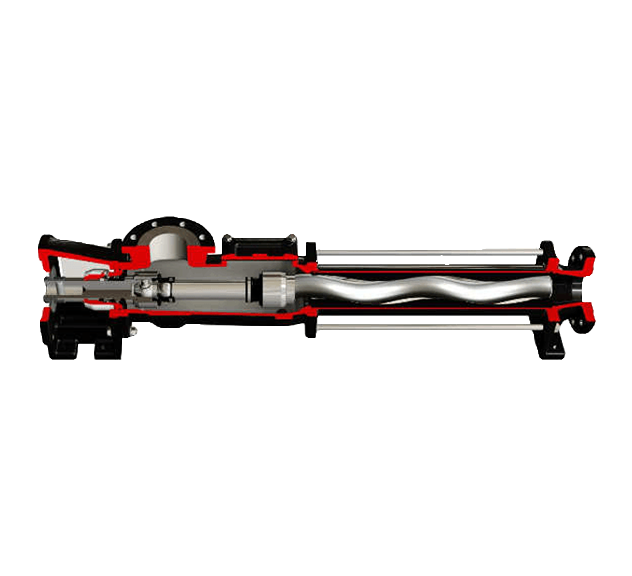

Our High-Pressure Dosing Diaphragm Pump is constructed for precision and reliability in the most demanding applications. These pumps are designed to handle liquids containing small amounts of suspended solid particles, and are perfect for dosing toxic, corrosive, and hazardous mediums where leakages are not permitted. Equipped with a diaphragm rupture detector and built to operate under high pressure, these pumps meet the stringent requirements of various industrial applications.

Typical applications for our High-Pressure Dosing Diaphragm Pump:

- Oil & Gas

- Chemical Processing

- Pharmaceutical

- Power Generation

- Petrochemical

- Pulp & Paper

Our High-Pressure Dosing Diaphragm Pump complies with API 675 and ATEX standards, ensuring high performance and safety in hazardous areas. Featuring an internal worm gear mechanism, fully lubricated in an oil bath, these pumps can be coupled with other units for multi-head configurations. Stroke adjustment can be performed manually or automatically, even during operation. The pumps maintain an accuracy of ±1% across 10-100% of their rated capacity. They include mechanical replenishment and an internal safety system to protect against overpressure and suction line obstruction.

- Strict Compliance: Meets API 675 and ATEX standards for enhanced safety and performance

- Flexible Coupling: Multiplex drive units can be independently coupled, regardless of size and stroke number

- Accurate Stroke Adjustment: Manual or automated stroke adjustment ensures precise flow control

- Built-in Safety System: Protects the pump from overpressure and suction line obstruction

- Reliable Diaphragm Design: Unique sandwich diaphragm with rupture detection system ensures leak-free operation

- Versatile Material Options: Wetted parts available in Stainless Steel 316L, PVC, PP, PVDF, PTFE, and more

- High-Pressure Capability: Suitable for demanding applications with high-pressure requirements

| Motor Power Range | 0.25 kW to 0.75 kW |

| Power Supply | Standard: 1Ph 230V (±10%) 50/60Hz, Optional: 1Ph 110V (±10%) 50/60Hz |

| Protection | IP55 |

| Ambient Temperature Range | 0 – 45°C |

| Ambient Altitude | Up to 1000m above sea level |

| Rated Motor Current at 230V | Up to 3.5 A |

| Overload Capacity | 150% continuous service |

Models:

- SDI 250: Stroke length 25 mm

- SDI 350: Stroke length 35 mm

- Various diaphragm sizes available for different capacities and pressures

Pumping Heads: Available in Stainless Steel 316L, PVC, PP, PVDF, PTFE

Custom Configurations: Multi-head units for varied performance requirements

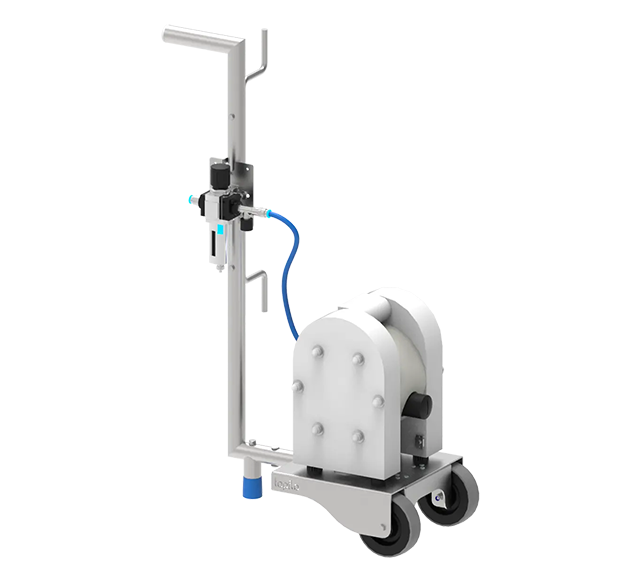

Additional Options:

- Filters: Ensure impurity-free dosing and protect the pump system

- Safety Valves: Prevent overpressure damage

- Back Pressure Valves: Maintain consistent discharge pressure and prevent siphoning

- Pulsation Dampeners: Reduce pressure fluctuations and ensure a nearly continuous flow