High Viscous Drum Unloading System

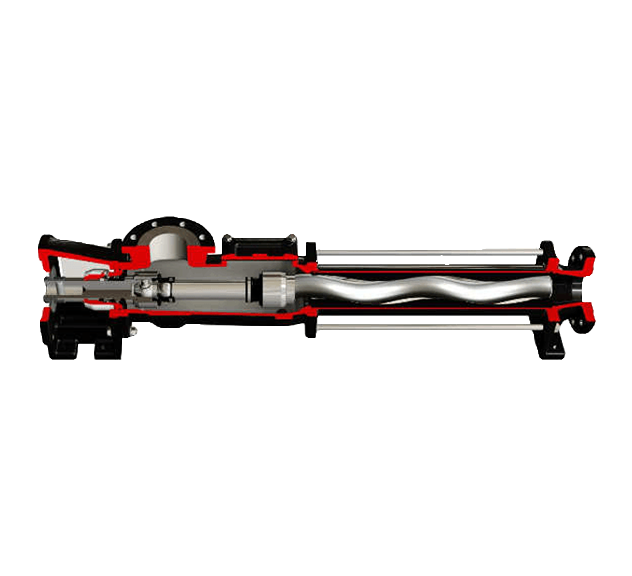

Our High Viscous Drum Unloading System is designed to handle high viscosity liquids in both Industrial and Sanitary settings. It efficiently empties barrels containing products such as tomato paste, coconut oil, tahini oil, resins and fruit and vegetable pulps. This pneumatically powered equipment uses actuators to raise and lower the pump, while the Diaphragm Pump operates through two diaphragms connected by a single diaphragm shaft. Alternately pressurising the air chambers behind the shaft and using an automatically cycled air valve system pushes the pump back and forth, enabling the discharge of high viscosity, paste-like, non-self-flowing media from the drums while ensuring efficiency and process safety.

Typical applications for our High Viscous Drum Unloading System:

Food & Beverage:

- Tomato pastes

- Caramels

- Fruit and vegetable concentrates

- Peanut butter

- Mayonnaise

- Nougat pastes

- Chocolate/fudge

- Glycerine oils

Pharmaceuticals & Cosmetics:

- Vaseline’s

- Ointments

- Creams and lotions

- Semi-solid waxes/paraffin

- Glycerine

- Oils

- Lip glosses

- Mascaras

- Facial cleansers

- The equipment is designed to provide a safe, simple and easy-to-use experience while ensuring low maintenance requirements

- Sealless construction eliminates the need for rotating parts, enhancing reliability and minimising downtime

- Compared to manual emptying, the system significantly reduces processing times, efficiently removing up to 99% of the product from the drum

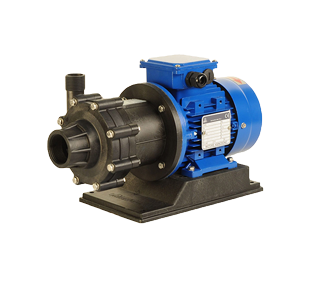

- Suitable for various duties in both Industrial and Sanitary installations, adhering to FDA and EN 10204 compliance standards

- With hygienic surfaces made from polished steel, the equipment ensures perfect cleanability. This not only reduces waste and associated costs but also facilitates a hygienic working environment

- You have the flexibility to choose between Lip Seal or Inflatable Seal options based on your specific needs. Additionally, an Optional Back-Up Diaphragm System with Rupture Detection further enhances system reliability

- The equipment’s installation options are highly flexible, allowing for direct container filling from palletised drums, providing added convenience and efficiency to the process

| Materials | Stainless Steel AISI 316L; electropolished/sandblasted |

| Max Capacity | 35.4m³/hr |

| Max Pressure | 80m |

| Drum Unloading | up to 400 l/min |

| Max Solids Size | 15mm |

| Max Temperature | 90ºC |

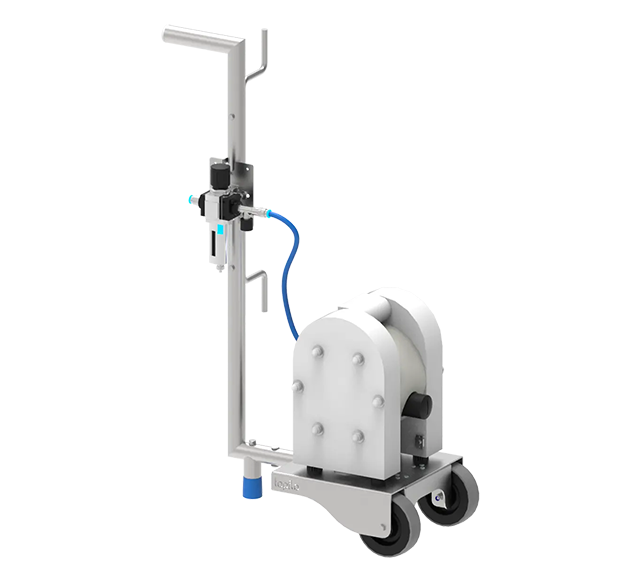

- High Viscous Drum Unloading System – Flexi

- High Viscous Drum Unloading System – Quattro

Flexi:

The HVS Flexi is used for the precise and efficient unloading of drums containing highly viscous liquids:

- Simplifies the unloading task through automation

- Ensures effective product extraction with a removal rate up to 99%

- Capable of handling liquids with viscosities up to 100,000 cPs

- Efficiently unloads 200L drums and accommodates IBCs (Intermediate Bulk Containers) and various other container types

- Equipped with an integrated control system for hassle-free operations

- Designed for applications with low to moderate volumes, making it an ideal solution for supplying filling or packing lines directly

- ATEX-rated for use in hazardous environments

Quattro:

The HVS Quattro is used to simplify drum switching, particularly when dealing with multiple drums on pallets, thanks to the articulated arm:

- Unloading speeds up to 400 l/min

- Effective product extraction with a removal rate up to 99%

- Capable of handling solids with a maximum passage of 15mm ( ball valve) and 42mm (flap valve)

- Features an integrated control system for easy and efficient operation

- Contact surface roughness of Ra <1.6 as standard, with <0.8 and <0.5 on request

- ATEX-rated for use in hazardous environments