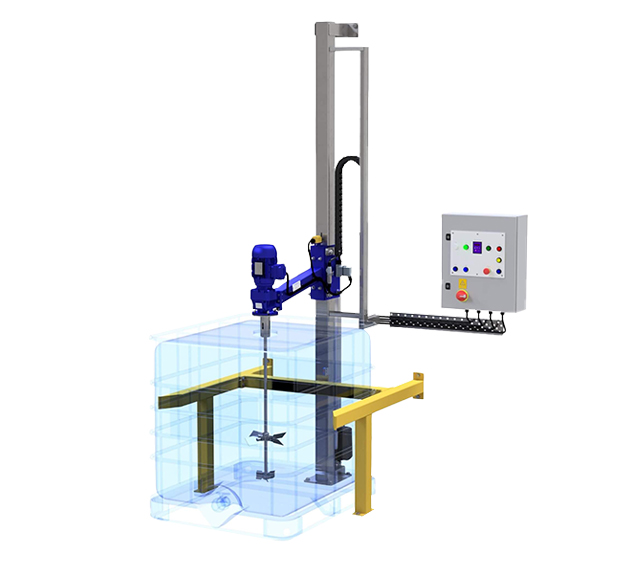

IBC Mixing Station

Max. Flow:

N/A

Max. Head:

N/A

Max. Temp:

N/A

Material:

Metal

Our IBC Mixers are precision-engineered for optimal mixing performance and efficiency within Intermediate Bulk Containers (IBCs) of diverse types and sizes. Built from durable, high-quality materials, these mixers guarantee thorough and consistent blending of liquids and powders, delivering a homogenous blend every time. Our IBC Mixers are equipped with all necessary components for immediate operation. Our team will assist you in selecting the perfect impeller, drive assembly and materials for superior mixing performance based on your operational requirements.

Typical industries and applications for our IBC Mixers:

Water/Solvent-Based Paints:

Glues:

Water Treatment:

Food:

Cosmetics:

| Viscosity cP | Mixer Model | Mixing | Drive Type | RPM | Impeller | Weight |

| 1 – 100 | HBC-037 | Mild – Medium | Motor | 1,400 | Fixed | 23kg |

| 1 – 100 | HBC-075 | Vigorous | Motor | 1,400 | Fixed | 25kg |

| 1 – 250 | LBC-037 | Vigorous | Gearmotor | 236 | Folding | 30kg |

| 250 – 1,000 | Mild – Medium | |||||

| 500 2,000 | LBC-075 | Vigorous | Gearmotor | 236 | Folding | 32kg |

| 2,000 – 5,000 | Mild – Medium | |||||

| 2,500 – 5,000 | LBC-150 | Vigorous | Gearmotor | 236 | Folding | 38kg |

| 5,000 – 15,000 | Mild – Medium |

Electric Motor (for <100cP viscosity)

Pneumatic (air) Motor

Gearbox – Electric or Pneumatic (for <15,000cP fluids)

Tell us what you need to pump and we will supply the solution!

Leave your contact number and our team will be in touch within 30 minutes!

If you have further questions, our Pump Specialists will have the answer. Please don't hesitate to get in touch:

Tel:

+971 4 2352717

Email:

sales@tapflogulf.com

Open hours between:

08:30-17:00 - Mon-Fri