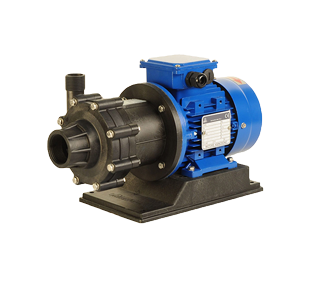

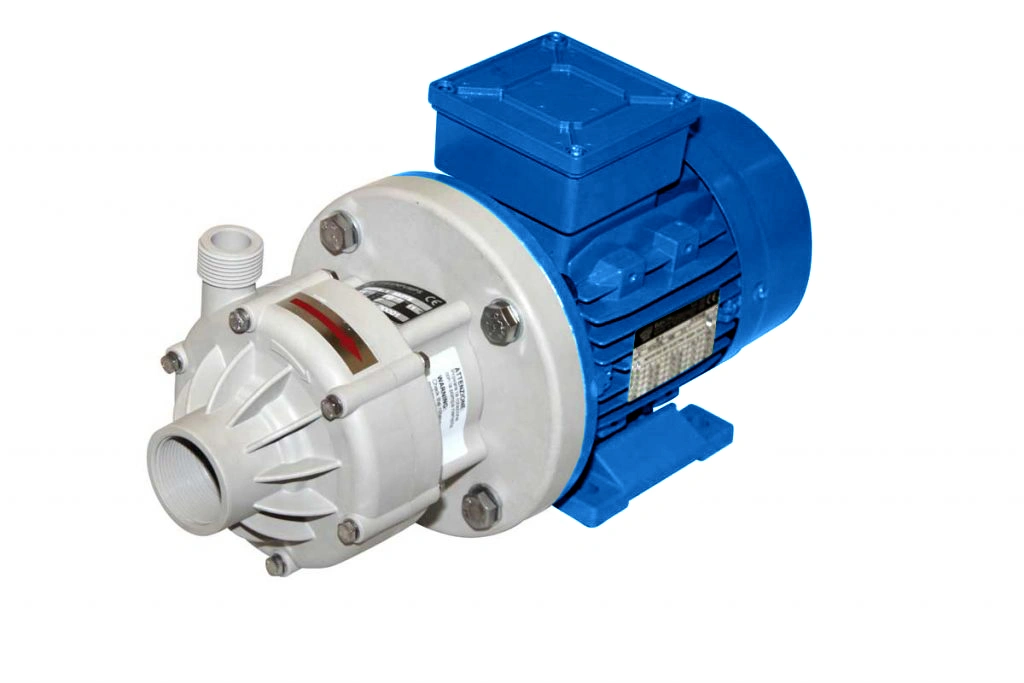

Injection Molded Mag Drive Centrifugal Pump

Our Injection Molded Mag Drive Centrifugal Pump ensures reliability and versatility in light-duty transfer applications. Crafted with precision using plastic-injected molded technology, these pumps are designed to resist internal and external corrosion, offering exceptional durability. Filled with fibreglass or fibre carbon materials, they are equipped to handle challenging solutions, including strong acids and difficult chemical compounds. With a commitment to environmental safety, these pumps are engineered to have zero leakages, eliminating dangerous emissions. Additionally, this pump can be ATEX-rated, providing additional safety in hazardous environments.

Typical applications for our Injection Molded Mag Drive Centrifugal Pump:

- Ideal for light-duty transfer applications in Chemical, OEM, and Industrial settings where corrosion resistance is crucial.

- ATEX-rated variant available for use in hazardous environments

- Resists internal and external corrosion due to construction from plastic injection molded Polypropylene (PP) or Polyvinylidene (PVDF)

- Filled with fibreglass or fibre carbon materials, designed to handle challenging solutions including strong acids and difficult chemical compounds

- Designed with construction features that ensure zero leakages, prioritising safety, and worker well-being

- The Injection Molded Mag Drive Centrifugal Pump can maintain head and flow for an extended running period, ensuring consistent performance

- High-torque neodymium magnets

- Channelled PTFEC carbon sleeve bearings resist chemical corrosion

- Modular impeller allows for easy modification of pump performances to suit requirements

- Direct starting motor

- Close-coupled NEMA and EC mounting options for ease of installation

- Replaceable adaptor motor flange

- Interchangeable coupling housings

- Separate Universal Hubs on External Magnet Ring allows for plug and play for any hub with any drive

- External Magnet Ring special design facilitates protection against physical damage

- Optional Dry Run Protection Module

| Materials | Polypropylene (PP), Polyvinylidene (PVDF) |

| Max Capacity | Up to 30m³/hr @ 50 Hz & up to 40m³/hr @ 60 Hz |

| Max Pressure | Up to 25m @ 50 Hz & up to 36m @ 60 Hz |

| Self Priming | No |

| Max Density | 2000kg/m³ |

| Max Temperature | Up to 65°C for PP & up to 90°C for PVDF |

| System Pressure | Up to 4 Bar |

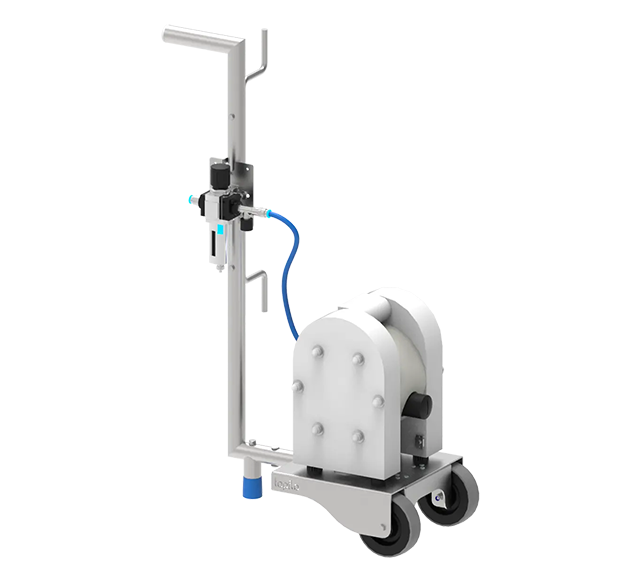

Dry Run Protector:

- Compact design

- Two internal current transformers

- Wide range current adjustment

- Definite trip time characteristic

- Manual (immediate)/Electric remote reset