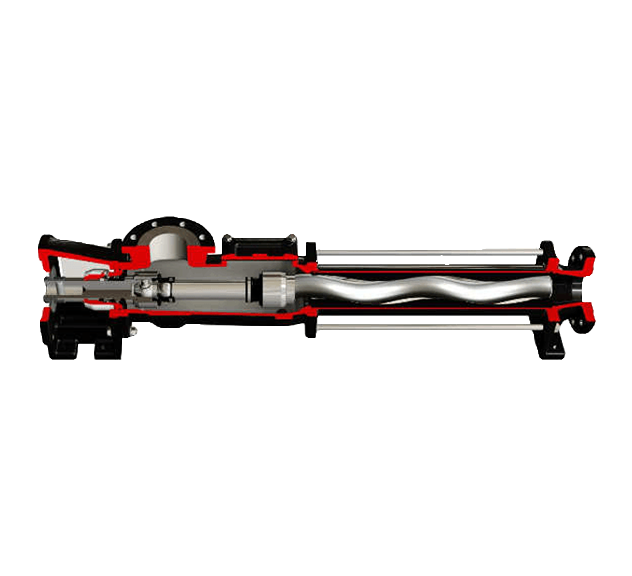

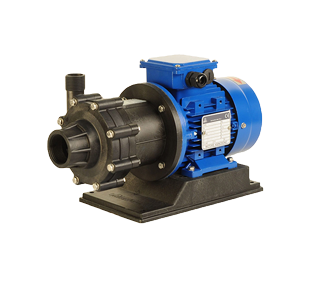

Solid Block Mag Drive Regenerative Turbine Pump

Our Solid Block Mag Drive Regenerative Turbine Pump is an ideal solution for fluid transfer with a focus on low-flow, high-head applications. Crafted from solid plastic materials such as PP or PVDF, these pumps resist internal and external corrosion, ensuring reliable performance even in harsh environments. The heavy-walled machined construction provides exceptional resistance to permeation and migration of corrosive substances. With a commitment to environmental safety, these pumps are designed with features to achieve zero leakages in extreme working conditions, while the absence of a mechanical seal or packing gland eliminates dangerous emissions.

Typical applications for our Solid Block Mag Drive Regenerative Turbine Pump:

- Ideal for medium-duty services, industrial cleaning, OEM filter system manufacturing, electroplating, fume scrubber, and CIP plant systems

- Built from solid plastic materials, the Solid Block Mag Drive Regenerative Turbine Pump resists internal and external corrosion, ensuring durability

- Heavy-walled machined construction provides superior resistance to permeation and migration of corrosive substances

- Engineered with construction features ensuring zero leakages, prioritising environmental safety and worker well-being

- Maintains head and flow for an extended running period

- Head up to 55m @ 50 Hz & 60m @ 60 Hz

- Flow up to 13m³/h @ 50 Hz & 15m³/h @ 60 Hz

- Temperature range from -40°C up to 90°C for PVDF & up to 65°C for PP

- Specific gravities up to 2 kg/dm³

- System pressure rating at 4 Bar up to 10 Bar depending on model and material

- Reversible rotation

- Suitable for thin non-lubricating mediums with a very low NPSH available value

- Can be used like a mixer, handling liquids with different characteristics

- High-torque neodymium magnets ensure high torque for optimal performance

- Low-flow high-head capability, minimising by-pass requirements for added efficiency.

- Heavy casing wall thickness

- Silicon carbide shaft

- PTFEC, SIC, or PTFEG bushings available on request

- Reinforced Containment Shell

- Replaceable impeller and casing front ring contribute to cost-effective operation

- Close-coupled NEMA and IEC mounting options for ease of installation

- High MTBF (Mean Time Between Failure), maximising operational reliability

- In accordance with ATEX regulation category EX II 2 G, ensuring adherence to safety standards

| Materials | Polypropylene (PP), Polyvinylidene Fluoride (PVDF) |

| Max Capacity | Up to 13m³/h @ 50 Hz & up to 15m³/h @ 60 Hz |

| Max Pressure | Up to 55m @ 50 Hz & up to 60m @ 60 Hz |

| Self Priming | Self-priming variant available |

| Max Temperature | Up to 90°C for PVDF & up to 65°C for PP |

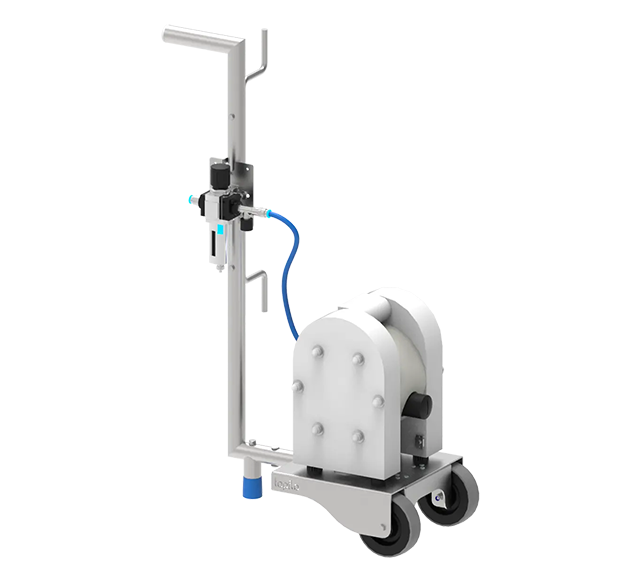

- Self-Priming/Long-Coupled Variants available on request

- Solid Block Mag Drive Plastic Regenerative Turbine Pumps

- Flanged ports ISO/ANSI

- ATEX execution

- Long-coupled configuration

- Self-Priming Variant

- Different bearing/shaft materials available