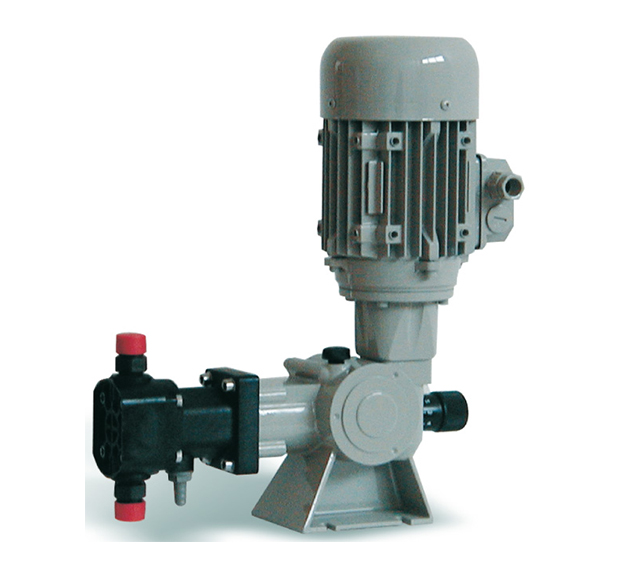

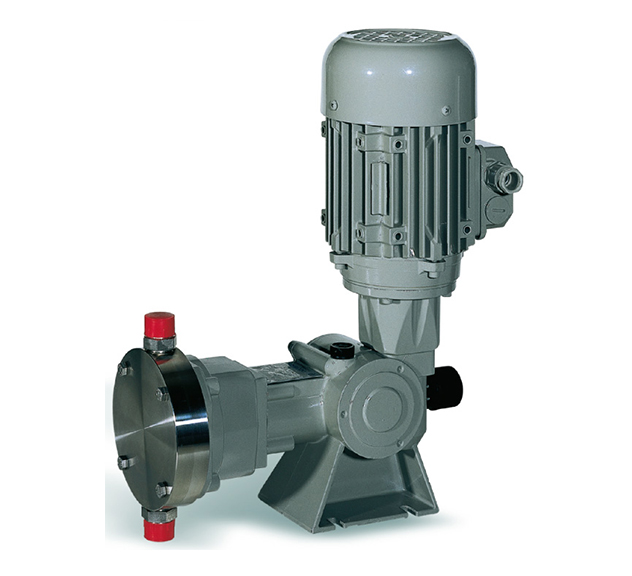

Spring Return Mechanical Diaphragm Pump

Tapflo Gulf is proud to be the exclusive UAE Partner of Doseuro, a leading Italian manufacturer of the highest-quality Metering Pump Solutions.

Our Spring Return Mechanical Diaphragm Pump forms part of our Metering & Dosing Pump range and is designed for precision in dosing applications involving toxic solutions and liquids with small amounts of suspended solids. Featuring airtight, drip-proof construction, this pump ensures safe operation without compromising on performance. Equipped with a standard gearbox reduction system and a vertical B14 shaped electric motor conforming to UNEL-MEC specifications, the Spring Return Mechanical Diaphragm Pump offers superior reliability and versatility for various industrial applications.

Typical applications for our Spring Return Mechanical Diaphragm Pump:

- Water Treatment

- Fertigation

- Food

- Cooling Towers

- Paper

- Chemical

Our Spring Return Mechanical Diaphragm Pump is an ideal choice for industries requiring precise and safe dosing of liquids containing suspended solids or toxic substances. This pump series features a robust gearbox reduction system, ensuring long-term reliability and minimal maintenance. The positive fore-stroke, spring return mechanism, controlled by an eccentric, guarantees precise control over the stroke length, making it adaptable for a wide range of applications.

- Delivers accurate and reproducible dosing of liquids containing small amounts of suspended solids

- Standard gearbox reduction system with a fully lubricated endless screw plus worm-wheel type mechanism

- Electric motors range from 0.18 KW to 0.37 KW, available in 3 phase (230/400V @ 50/60Hz) and 1 phase (230/50/60 Hz or 110/60 Hz) configurations

- Several sizes available to grant capacities from 4 l/h up to 1400 l/h, with a variety of materials for wetted parts (PVC, PP, PVDF, S.S.316L, PTFE)

- Motors conform to UNEL-MEC specifications, which are universal parameters to be followed for the construction of electrical motors, ensuring compatibility with various voltage and insulation classes, including ATEX-rated variants

- Airtight, drip-proof design ensures safe operation with toxic liquids

- Can be fitted with various accessories such as polyethylene tanks, relief valves, back pressure valves, safety relief valves, injection valves, foot valves, pulsation dampeners, and calibration pots

| Motor Power Range | 0.18 KW to 0.37 KW |

| Voltage Options | 3 phase: 230/400V @ 50/60Hz, & 1 phase: 230/50-60 Hz or 110/60 Hz |

| Piston Sizes | 4 l/h to 1400 l/h |

| Gearbox Type | Endless screw plus worm-wheel, fully lubricated |

| Stroke Mechanism | Positive fore-stroke, spring return, operated by an eccentric |

| Mounting | Vertical B14 shaped electric motor |

| Compliance | UNEL-MEC specifications |

Model Variations:

- D050N: 49 l/h, 14 Barg

- D100N: 374 l/h, 5 Barg

- D101N: 408 l/h, 8 Barg

- D121N: 574 l/h, 3 Barg

- D122N: 1400 l/h, 6 Barg

Our Spring Return Mechanical Diaphragm Pump series offers several variations to cater to different industrial needs:

- Standard Model: Ideal for general applications requiring precise dosing of liquids with suspended solids

- High Capacity Model: Designed for applications requiring larger volumes, equipped with higher capacity models up to 1400 l/h

- Explosion-Proof Model: For use in hazardous environments, featuring ATEX-rated motor variants.

- Custom Material Model: Offers customised wetted parts in materials like PVC, PP, PVDF, S.S.316L, and PTFE to match specific operational requirements