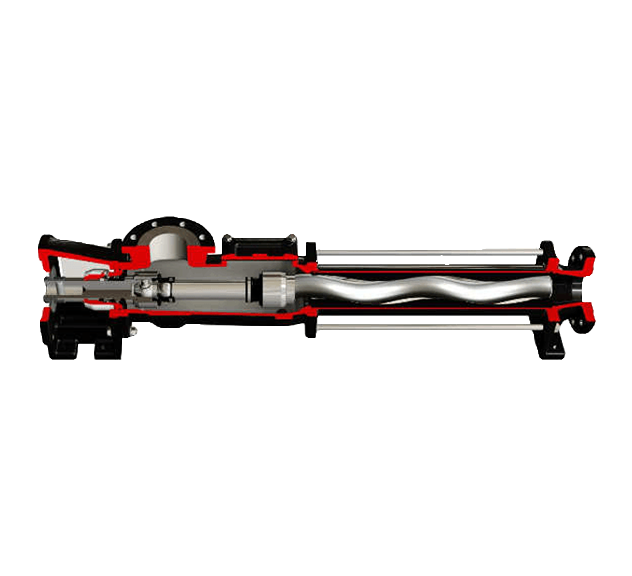

Plunger Pump

Tapflo Gulf is proud to be the exclusive UAE Partner of Doseuro, a leading Italian manufacturer of the highest-quality Metering Pump Solutions.

Our Plunger Pump is a type of Positive Displacement Pump designed to deliver precise and reliable performance in the most demanding environments. Used in applications where the pumped liquid must be free of suspended solid particles and where leakage is unacceptable, these pumps are ideal for handling toxic, corrosive, and hazardous fluids. These pumps are ATEX-rated and are capable of achieving high pressures, making them suitable for a variety of industrial applications.

Typical applications for our Plunger Pump:

- Chemical Processing

- Oil & Gas

- Water Treatment

- Pharmaceuticals

- Food & Beverage

Our Plunger Pump complies with API 675 and ATEX standards, ensuring high performance and safety in hazardous areas. These pumps feature an internal worm gear mechanism, fully lubricated in an oil bath, and offers the flexibility of coupling with other units for multi-head configurations. Stroke adjustment is precise, with manual or automatic options available, and the pumps maintain an accuracy of ±1% across 10-100% of their rated capacity. Optional flushing or leakage recovery systems ensure reliability and ease of maintenance.

- Compliance: Meets API 675 and ATEX standards for safety and performance

- Flexible Coupling: Multiplex drive units can be independently coupled regardless of size and stroke number

- Accurate Stroke Adjustment: Manual or automated stroke adjustment ensures precise dosing

- Low NPSH Requirement: Optimised for normal operating conditions

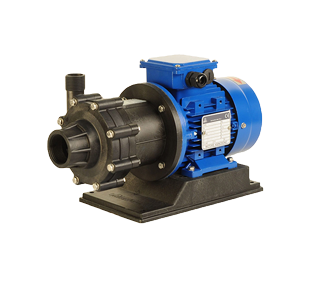

- Versatile Material Options: Wetted parts available in Stainless Steel 316L, PVC, Hastelloy, Alloy, PTFE, PVDF, or PP

- High-Pressure Capability: Suitable for demanding applications with high-pressure requirements

- Enhanced Fluid Control: Optional filters, safety valves, back pressure valves, and pulsation dampeners ensure safe and efficient operation

| Motor Power Range | 0.55 KW to 1.1 KW (SS316) & 0.55 KW to 1.1 KW (PVC) |

| Voltage Options | 3 phase: 230/400V @ 50/60Hz, & 1 phase: 230/50-60 Hz or 110/60 Hz |

| Diaphragm Sizes | 1.5 l/h to 1068 l/h |

| Gearbox Type | Endless screw plus worm-wheel, fully lubricated |

| Stroke Mechanism | Positive fore-stroke, spring return, operated by an eccentric |

| Mounting | Vertical B14 shaped electric motor |

| Compliance | UNEL-MEC specifications |

- Pumping Heads: Available in S.S. 316L or PVC, with other materials on request

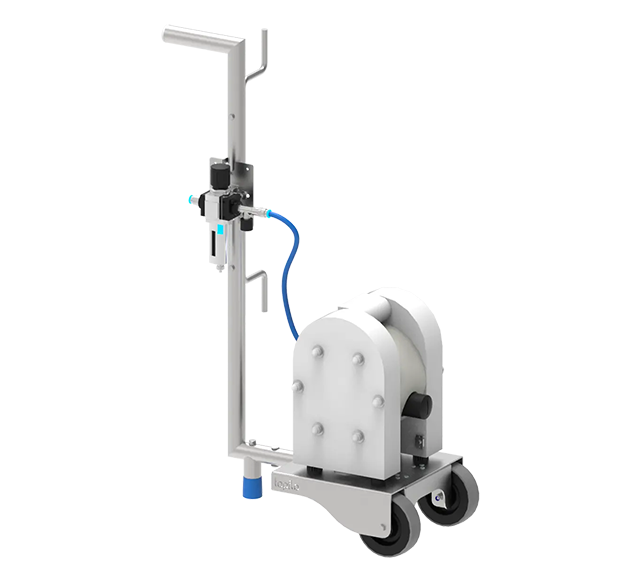

- Stroke Adjustment Mechanisms: Manual, electrical, or pneumatic options

- High-Pressure Execution: Enhanced hydraulic components for high-pressure applications

- Customised Configurations: Multi-head units for varied performance requirements

Additional Options

- Filters: To ensure impurity-free dosing and protect the system.

- Safety Valves: To prevent overpressure damage.

- Back Pressure Valves: To maintain consistent discharge pressure and prevent siphoning.

- Pulsation Dampeners: To reduce pressure fluctuations and ensure nearly continuous flow