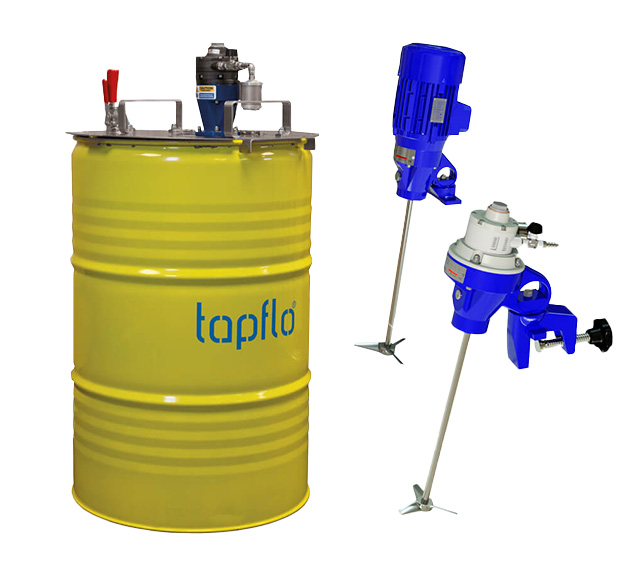

Drum Mixers

Max. Flow:

N/A

Max. Head:

N/A

Max. Temp:

N/A

Material:

Metal

Our Pneumatic Mixing & Emptying System, also known as a Pneumixer, is designed to meet the unique needs of the Paint & Ink industry where raw materials are stored in containers and tend to settle over time. These materials typically need to be mixed or blended before use. Traditionally, mixing raw materials involved time-consuming and messy processes like rolling, shaking or pumping materials into a separate vessel, leading to wastage and increased costs. The Pneumixer changes this by seamlessly integrating with the original container, securely fitting into the vessels fill-hole.

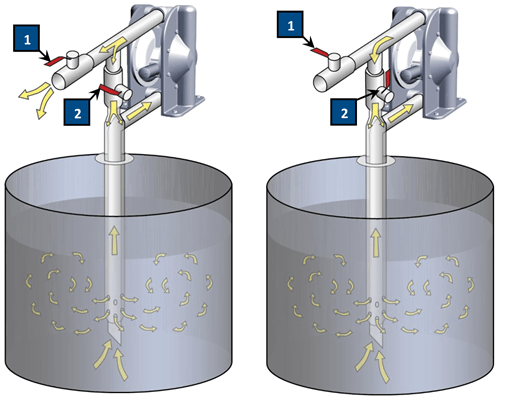

Typical modes for our Pneumatic Mixing & Emptying System:

Transfer Mode (image on the left):

Open the discharge valve (1) and partially open the recirculation valve (2) for efficient product mixing and transfer out of the vessel.

Mixing Mode (image in the right):

Close the discharge valve (1) and open the recirculation valve (2) to facilitate product circulation within the vessel.

Stopping the Pump:

For enhanced protection and functionality, consider adding Tapflo’s Pneumatic & Electronic Protection Systems for extended pump and Pneumixer protection.

Tell us what you need to pump and we will supply the solution!

Leave your contact number and our team will be in touch within 30 minutes!

If you have further questions, our Pump Specialists will have the answer. Please don't hesitate to get in touch:

Tel:

+971 4 2352717

Email:

sales@tapflogulf.com

Open hours between:

08:30-17:00 - Mon-Fri