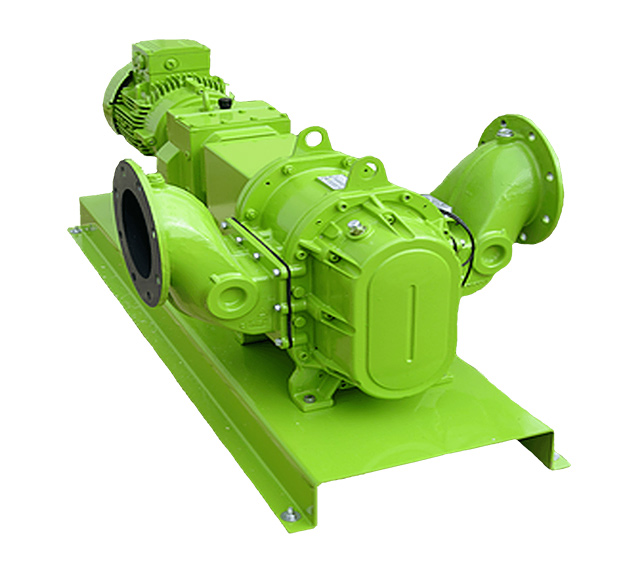

Sanitary Lobe Pump

Our Sanitary Lobe Pump is a versatile Positive Displacement Pump specifically designed for the hygienic processing industry. The difference between the Sanitary Lobe Pump and a Gear Pump is that, unlike a Gear Pump, the Lobe Pump features lobes that don’t physically touch, providing significant advantages for certain media types including pumping both low and high-viscosity products with minimal shear forces. Designed for energy efficiency, this pump boasts a special rotor-shaft mounting for accurate positioning and a backlash-free connection, accommodating lubrication and accounting for thermal expansion. The unique gear housing design eliminates cross-contamination of the pumped product with gear oils, ensuring a clean and hygienic operation.

Typical applications for our Sanitary Lobe Pump:

- Bakery Products

- Beverage Production

- Canned Goods

- Confectionary Products

- Cosmetics

- Dairy

- Meat Production

- Pharmaceuticals

- Chemical

- Efficiency: this pump ensures optimal performance with its low noise, minimal shear forces and excellent energy efficiency

- Design & Execution: the pump’s design offers great flexibility, featuring a 4-directional gear housing mounting, allowing for bi-directional flow and the option for horizontal or vertical mounting. Additionally, the spacious cavities and large spaces between lobes enable the gentle pumping of liquids containing significant solids

- Various Sizes: with 8 different sizes available across the range of models, this pump can handle a maximum capacity of up to 82 m3/hr and a pressure of up to 10 Bar

- Tailored to Your Needs: the wide range of executions and sizes within this pump series make it highly customisable, ensuring it can be tailored precisely to meet your specific requirements

- Easy Maintenance: the pump body and cover can be quickly and easily removed and installed for repair purposes

- Reliable Mechanical Seal: the pump comes with a single mechanical seal as a standard feature, with the option to request double mechanical seals. Pumps with flush double mechanical seals can run dry continuously

- Contamination-Free: thanks to its unique gear housing design, the pump ensures complete isolation of the gear oil from the pumped fluid zone, preventing any risk of cross-contamination

- Suitable for CIP/SIP: the pump is well-suited for CIP (Clean in Place) and SIP (Sterilise in Place) processes, ensuring thorough cleaning and sterilisation

- Hygiene & Safety Assurance: the pump is constructed using FDA-approved food contact materials and it is fully compliant with CE standards, guaranteeing both hygiene and safety in its operation

| Materials |

Stainless Steel AISI 316L |

| Max Capacity |

82m³/hr |

| Max Pressure |

100m |

| Self Priming |

Yes |

| Max Solids Size |

15mm |

| Max Temperature |

100ºC |

-

-

Vertical Inlet/Outlet

-

-

Stainless Steel Baseplate

-

-

Lubrication Tank

-

-

Thermosyphon Tank

-

-

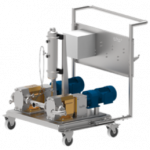

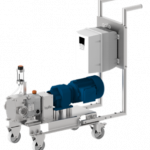

Mobile Tailor Made Solutions

-

-

Trolley & Inverter

-

-

IP66 Inverter

- Vertical inlet/outlet for pump drainability and easier flow into the suction connection

- AISI 304L stainless steel baseplates as standard for all pump sizes

- Lubrication tank for media crystallising in contact with air

- Tank using thermosyphon effect for heavy-duty applications

- Mobile solutions tailored to specific needs of clients

- Standard Tapflo trolleys and IP66 inverters

- IP66 inverters available in stock with fast delivery times