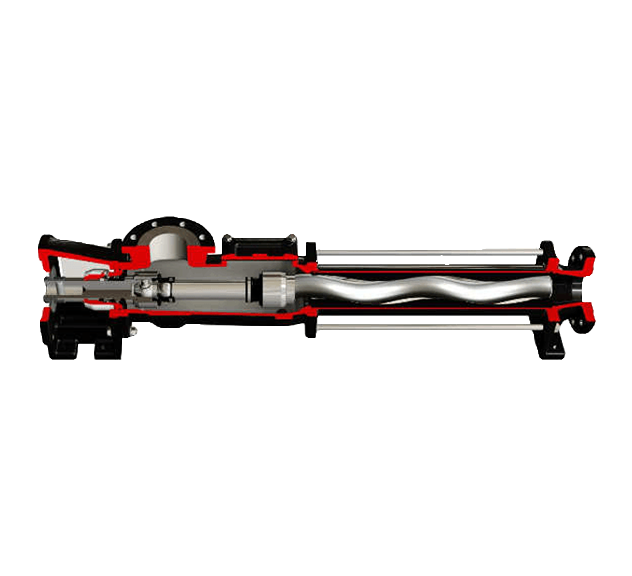

Sliding Vane Pump

The operation of a Sliding Vane Pump is characterised by an eccentrically mounted slotted rotor rotating within a stator (pump body). Thanks to the mounting of the rotor within the stator, a crescent-shaped cavity forms at the base of the stator. As the rotor turns, the sprung-loaded vanes, which are mounted into the slots of the rotor, slide in and out, trapping fluid between themselves and moving them through the crescent cavity towards the pump discharge under pressure. The tight seal and tolerances between the vanes, stator & side plates facilitate excellent suction capabilities.

The Sliding Vane Pump from Jump is ideal for a range of industries, not limited to:

Food Industry

Hydrocarbons: Fuel, Oil

Chemical Industry: Acids, Solvents, Glues

Wine Industry

Excel at handling low viscosity liquids such as LP gas (propane), ammonia, solvents, alcohol, fuel oils, gasoline and refrigerants

No internal metal-to-metal contact and self-compensate for wear, enabling them to maintain peak performance.

Reduced maintenance time due to innovative disassembly of the seal from the front without uncoupling the gear motor and piping

Though efficiency drops quickly, they can be used up to 500 cPs

Front pull-out seal replacement

Dry running capabilities

Reversible

Self-priming

Optional Integrated Double By-Pass and Heating Jacket

Temperatures up to 250˚C

Differential pressures up to 120 meters

FDA Approved and ATEX rated

Mechanical seal DIN 24 960 (EN 12 756)

Capacity Range: Up to 140 m³/hr

Pressure Range: Up to 120 meters

Temperature Range: -10˚C to +250˚C

Rotor Materials: Ductile Iron or Stainless Steel AISI 316L

Vanes Materials: Ductile Iron, PEEK, Bronze, Steel

Heating Jacket: Optional

Materials Options

Rotor: Ductile Iron, 316L Stainless Steel

Vanes: Ductile Iron, PEEK (option bronze, steel, etc)

Body/Front Cover/ Foot/ Bypass /Shaft: Ductile Iron, Steel, 316L Stainless Steel

Bearings: Carbon (options, bronze, ductile iron, PEEK, etc)

Seals: FKM (option FEP/FKM, EPDM)

Screws: Steel, 316L Stainless Steel

To be confirmed