Steel Centrifugal Pump

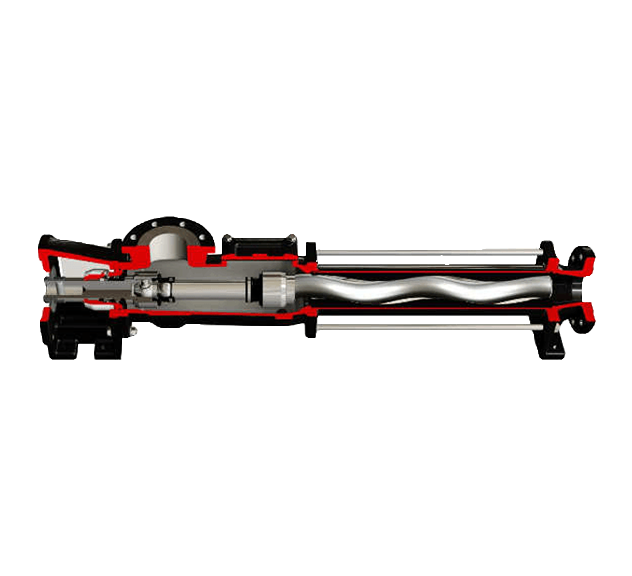

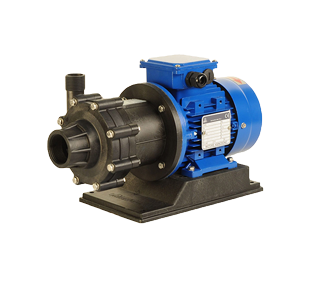

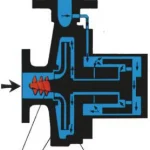

Our Steel Centrifugal Pump, constructed from Stainless Steel AISI 316L, is a reliable solution for various industrial applications. Compliant with ISO5199/ISO2858/DIN24256 regulations, these Centrifugal Pumps are designed for high efficiency and a low NPSHr value. Available in numerous different configurations such as close or long coupled (with spacer coupling) and API 685 compliance, these pumps prioritise safety, efficiency, and environmental protection. The design features front suction and vertical configurations, eliminating the need for air removal before starting, while the absence of mechanical seals ensures no dangerous emissions even in challenging conditions. Numerous options are also available to customise these units to specific and challenging applications such as heating or cooling jackets, external heat exchangers, and low NPSHr Impeller configurations.

Typical industries for our Steel Centrifugal Pump:

- Chemical (including hazardous chemicals)

- Pharmaceutical

- Refineries

- Paper Mills

- Textiles

- Food Processing

- Sugar Plants

Technical Design Features:

- Casing built with heavy wall thicknesses; flanges machined to 150 or 300 ANSI standard

- One-piece .050” Hastelloy C276 containment housing exceeding ASME pressure vessel codes

- External lubrication for dead-head operation

- Impeller pump-out vanes balance axial thrust

- Silicon carbide sleeve and thrust bearings capable of intermittent dry running

- Interchangeable mag-couplings & spare parts

- Hand-fit sleeve bearings & components

- Replaceable casing wear ring

- Back Pull-Out design

- Quick-change rear cartridge assembly for replacement and restart within 10 minutes

- Containment Shell is isolated from hydraulic loading of the pump shaft as the internal bearing housing and shaft are supported by the pump frame.

Standard Features & Benefits:

- High efficiency and low NPSHr value

- Robust construction to prevent dangerous liquid leaks in challenging conditions

- Absence of mechanical seals or packing glands eliminates dangerous emissions (designed to protect workers and the environment)

- Available in compact or basic coupling configurations

- API685 standard version for specific applications

- Hydraulically balanced impeller via counter-blading for pumping low-boiling liquids

- Few rotating parts ensure a High Mean Time Between Failures (MTBF) value

- Available in Stainless Steel AISI 316L, Alloy 20, Incoloy 825, Hastelloy B-C, Monel and Titanium

- Common maintenance components between models within the same size

- Modular design results in fewer spares and reduced costs

- Quick-change cartridge deign for easy maintenance

- Internal cartridge (rear wet end) with an inducer for low NPSH

- Designed for accessing the power frame without exposing process fluid to the atmosphere

- Dual ‘back-pull’ design for servicing hydraulic end or ball bearing assembly

| Materials | Stainless Steel, Incoloy, Alloy, Hastelloy, Monel, Titanium |

| Max Capacity | Up to 1,000m³/hr @ 50 Hz & 600m³/hr ~ 60 Hz |

| Max Pressure | Up to 140m @ 50 Hz & up to 200m ~ 60 Hz |

| Self Priming | No |

| Max Temperature | Up to 315ºC |

- Jacketed Steel Centrifugal Pump

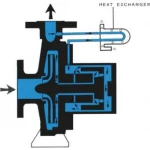

- External Heat Exchanger

- LOW NPSH Steel Centrifugal Pump

- Steel Centrifugal Pump Back Pull Out Design

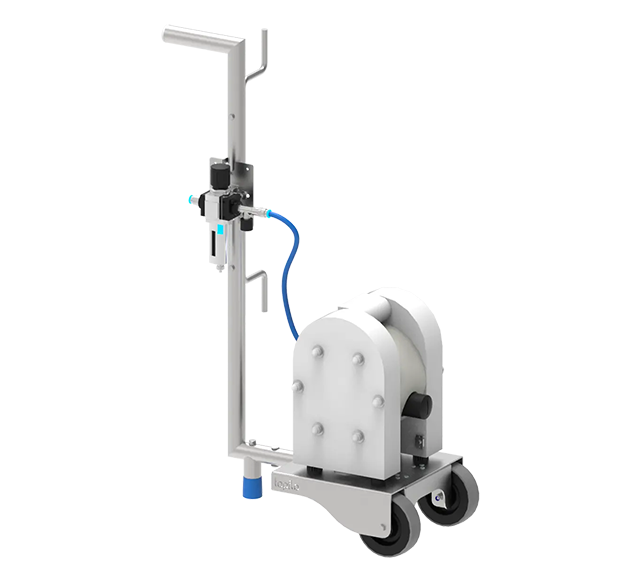

- Jacketed Pumps (sealless magnetic drive) for pumping liquids prone to solidifying at low temperatures or heat-sensitive liquids

- External Heat Exchanger (sealless magnetic drive) for liquids over 300°C

- Low NPSH Pumps (sealless magnetic drive) with optional inducer for applications with very low N.P.S.H. (it’s important to note inducers are designed for specific duty points to provide uniform eye velocity. Further, if operated outside +10% -20% of the rated capacity, an inducer will generally harm N.P.S.H. performance)