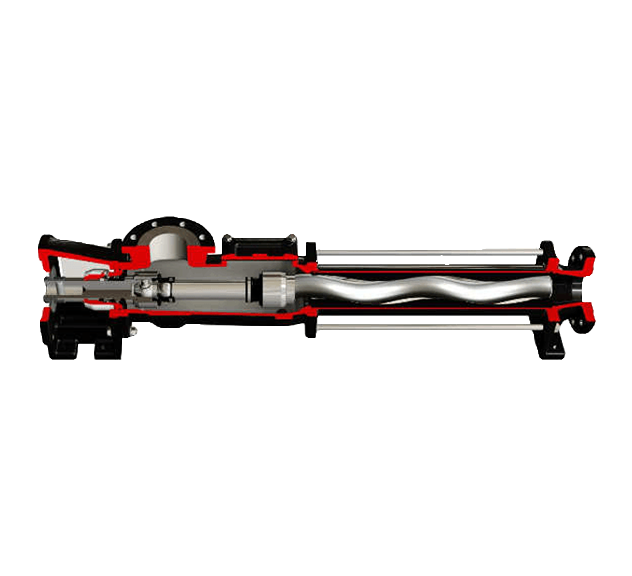

Two Stage Regenerative Turbine Pump

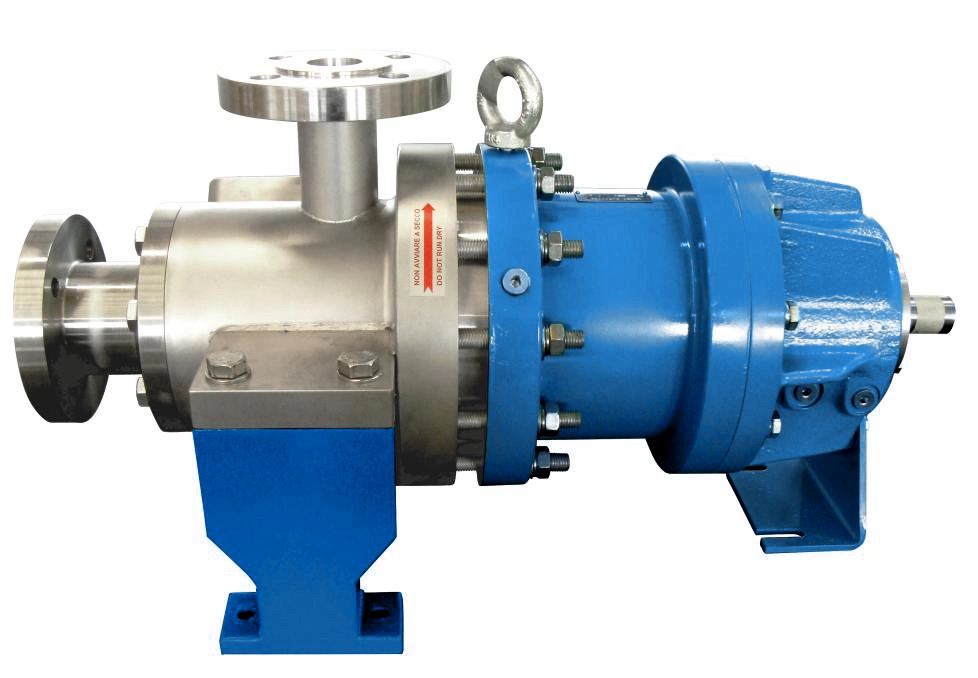

Our Two Stage Regenerative Turbine Pump is a specialised solution designed for low NPSHa, low flow, and high head applications. A variation of our Alloy Turbine Pump, this Regenerative Turbine Pump’s unique double-stage construction features a Francis vane centrifugal impeller at the first stage and one/two regenerative turbine impellers to flood the second and/or third stages (three stages with 2 booster impellers available on request). API685 compliant, barrel type, end-suction, top-discharge, and centreline mounted, this pump is particularly suited for handling liquefied gas, condensate hydrocarbons, ammonia, and cryogenic liquids.

Typical Industries for our Two Stage Regenerative Turbine Pump:

- Water Treatment

- Pharmaceutical

- Chemical

- Petrochemical

- Refinery

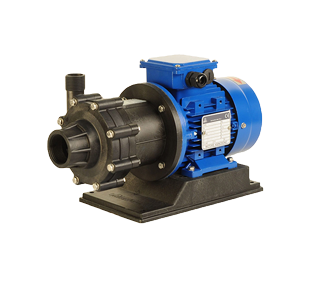

- Sealless & Leak-Free Mag Drive Construction

- Close & Long Coupled Configurations

- Double-stage design tailored for low NPSHa, low flow, and high head applications

- Smooth and balanced pumping action through the regenerative principle

- Impeller magnet floats freely, ensuring long life and trouble-free service

- Differs from centrifugal Pumps in that the fluid travels through vanes multiple times, offering higher pressure-building capability

- Suitable for clean fluids and systems with close internal clearances

- Double-stage floating impeller design prevents thrust load on motor bearings

- Hydraulic self-centering in the impeller cavity for stability

Benefits of the Regenerative Turbine Principle:

- Fluid is directed to both sides of the impeller, creating a drawing force

- Circulatory flow through the vanes generates fluid velocity

- Multiple cycles of regeneration result in pressure-building capability

- Two-sided floating impeller design for stability

| Materials | Stainless Steel AISI 316L casing, Hastelloy C276 for wetted parts |

| Max Capacity | 14m³/hr |

| Max Pressure | 400m |

| Self Priming | Yes |

| Max Temperature | 315ºC |

| NPSHr | <1m |

- Long-coupled configuration

Two Stage Long-Coupled Configuration is suitable for specific applications requiring a long-coupled design.

- API685 Standards compliance

- Double containment shell with a mechanical seal on the coupling housing

- NPSHa: 1.5m