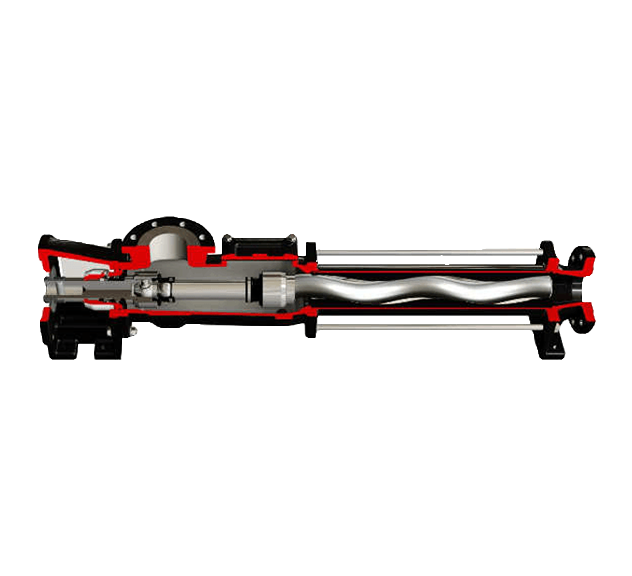

Volumetric Vane Pump

Our Volumetric Vane Pumps, constructed from Stainless Steel AISI 316L, with a range of additional materials available on request, are ideal for use across the Water Treatment, Pharmaceutical, Chemical, Petrochemical, Refinery, and Pulp & Paper industries. Thanks to their robust construction, these Sliding Vane Pumps are ideal for pumping poorly lubricated liquids while minimising the risk of leaks, even in challenging operating conditions. Additionally, they excel at maintaining constant pressure during normal operation and are built for low flow rates and high heads, with differential pressure capabilities that automatically adjust. Due to their internal graphite vanes that automatically compensate for wear due to sliding, these Volumetric Vane Pumps can maintain the required pressure and flow rate for extended periods of time.

Applications for our Volumetric Vane Pumps:

- Pumping dangerous, radioactive liquids

- Transfer of solvents, acids, alkalis, and refrigerants

- Pilot plants

- Refineries sampling

- Mechanical seal flushing

- Chemical processing

- Hydrocarbon processing/refining

- Municipal, such as scrubber systems

- Biofuels

- Hygienic & Pharmaceutical

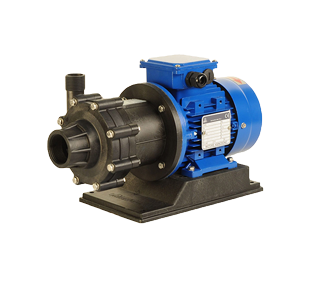

- External magnet fully enclosed for safety and durability

- Standard bronze ring (bushing) in the pump coupling for enhanced engine performance

- Safely self-primes without pump damage

- Friction-free operation as there is no metal-to-metal contact for reduced wear

- Can run efficiently with an inverter

- Heavy-duty machined pressure parts

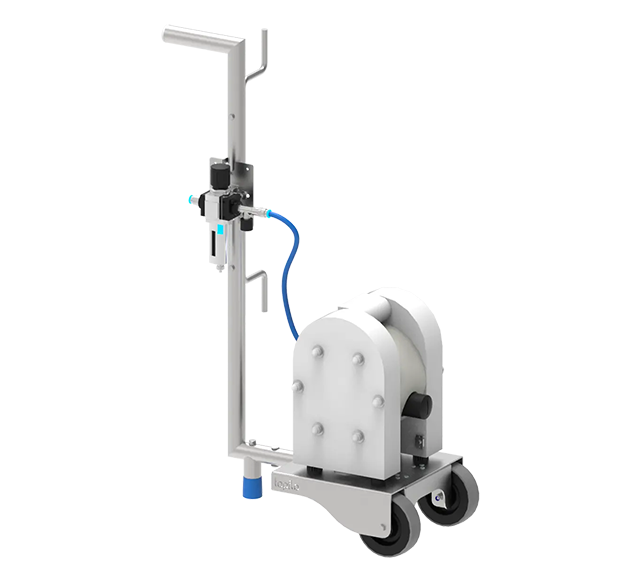

- Easily replaceable internal cartridge for quick maintenance

- Designed for cost-effective maintenance

- High Mean Time Between Failures (high MTBF)

- High-torque magnets (Samarium Cobalt Magnets) for optimal pump performance

- Foot support availability across the range

- ATEX-rated for category EX II 2 G for safety assurance

| Materials | Stainless Steel AISI 316L, Incoloy 825, Alloy 20, Hastelloy C-276, Duplex, Titanium |

| Max Capacity | 120m³/hr |

| Max Pressure | 130m |

| Self Priming | Yes, up to 2.5m in water |

| Max Temperature | Up to 250ºC |

| Viscosity | 2,000 cPs |

- Tri-Clamp Connections for Sanitary applications

- High-Pressure Volumetric Vane Pump

- Volumetric Vane Pumps for Polyurethane applications

- Flanged ports ISO/ANSI

- Tri-clamp ports

- High and low-temperature designs

- High-pressure design

- Special polished finishing

- Hygienic execution available on request

- Jacketed coupling housing

- Jacketed end cover

- Thermowell