Mobile Pump Trolley for Railway Maintenance

Our client, a prominent manufacturer and supplier to the Railway industry, approached us when they required a custom solution for emptying jerry cans and we were delighted to extend our support and expertise to meet their unique needs.

The Challenge

The end-user sought a specialised pump trolley tailor-made for their specific requirements. Their challenge was to efficiently empty 25L jerry cans, containing a toilet cleaning product, within just 1 minute. Embracing the opportunity, Tapflo Gulf’s expert team immediately got to work to deliver a seamless solution.

The Solution

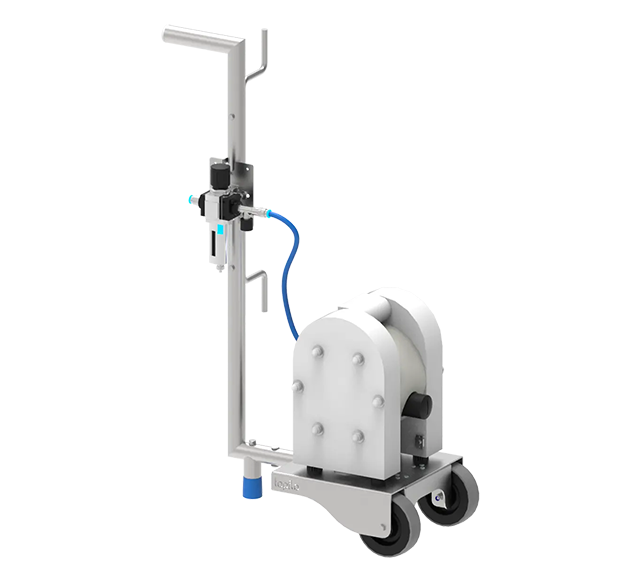

To ensure a truly mobile and versatile solution capable of crossing railway tracks without obstruction, we realised that traditional electric lines running along the floor were not viable. In response, our skilled Technical Engineering Team at Tapflo Gulf designed an innovative, power-independent system that would operate solely on a rechargeable battery.

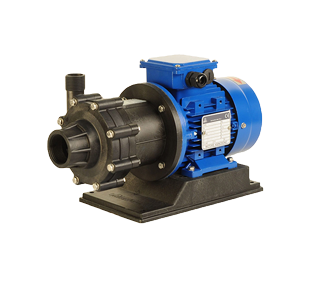

The trolley system was fabricated to withstand the challenges of railway environments. We incorporated a robust 17AH-rated battery that provided up to 1 hour of operation before requiring recharging. This capacity allowed approximately 60 toilets to be serviced on a single charge. To minimise the electrical requirements and reduce the trolley’s footprint, we integrated a 24v DC Pump and battery/buffer module to handle the motor’s high amperage pull during startup.

Safety and practicality were paramount in the design. The trolley featured large puncture-proof wheels (260 x 85 mm in diameter) with two swivelling at the front and two brake swivels at the rear for easy manoeuvrability. Additionally, we installed a battery monitor, conveniently placed under an ergonomically designed push bar, providing the operator with real-time battery status updates.

The trolley’s construction incorporated protective measures, including a top removable cover to shield it from environmental conditions and potential accidental damage. Furthermore, the electrics were safely housed within their dedicated control panel for additional protection. Adhering to industry standards, the trolley was expertly painted Sun Yellow with a signal black push bar.

Features & Benefits of this Solution

- The hour-long battery life empowers the operator to service around 60 toilets on a single charge

- Protected against environmental factors, ensuring optimal performance in railway environments

- Compact footprint for easy navigation through doorways and tight spaces

- Discharge hose wrap support facilitates convenient storage when not in use

- Specially designed storage space for two 25L jerry cans, with a skeletal frame to allow easy run-off/drainage in case of spillage

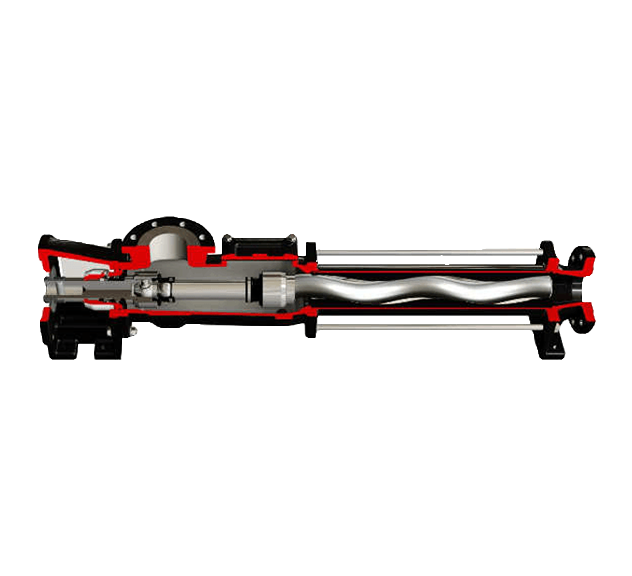

- Utilisation of Flexible Impeller Pumps, known for their self-priming capabilities, robust design and chemical resilience

- Ergonomic push bar design for effortless manoeuvrability

- Stainless steel trolley frame with rolled edges for added operator safety

Conclusion

At Tapflo Gulf, we take pride in our ability to design and construct customised solutions that precisely match our clients’ requirements. Whether you’re looking for a comprehensive solution or a bespoke design for your industry-specific needs, our Technical Engineers are always ready to assist you. Get in touch with our team today to embark on your journey towards pumping excellence. Additionally, you can explore our comprehensive range of case studies to explore the diverse solutions we’ve provided to clients over the years.