Process Pump Certifications – Your Guide to Quality & Safety

Sections:

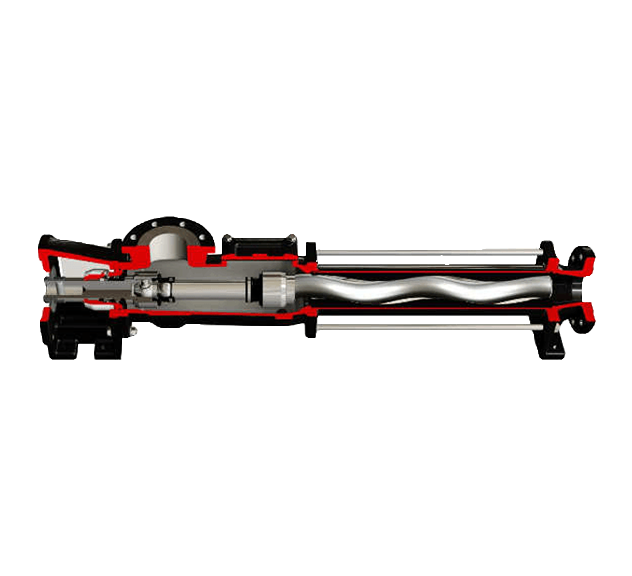

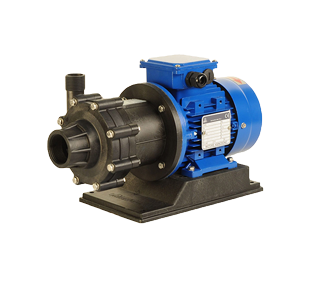

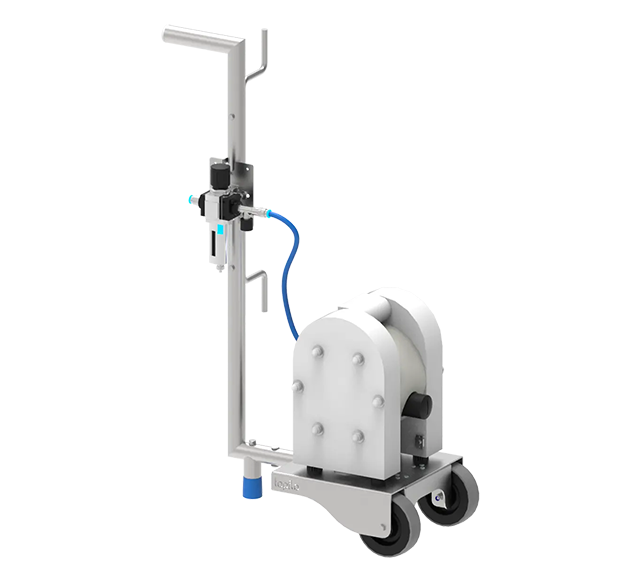

In the world of process pumps, ensuring the highest levels of quality and safety is vital. When it comes to handling materials that will come into contact with human tissue, food products or potentially explosive atmospheres, adherence to strict standards and certifications is not only desirable but often mandatory. At Tapflo Gulf, we prioritise your safety and the quality of our products. In this article, we’ll explore some of the key standards and certifications that we adhere to in order to provide you with reliable and safe process pumps.

USP VI Approved Materials

- The U.S. Pharmacopeial Convention (USP) Class I to VI standards define the suitability of plastic or rubber materials for contact with human tissue

- Class VI is the most strict and is required for applications like implant devices

- Tapflo Gulf ensures that our materials meet USP Class VI standards, a basic requirement for medical device manufacturers

EHEDG-Certified Products

- The EC Machinery Directive outlines design considerations for hygienic pump applications

- EHEDG (European Hygienic Engineering & Design Group) certification confirms compliance with hygienic guidelines

- Stringent testing ensures product safety, reduces contamination risk and simplifies cleaning, saving you time and effort

FDA §21 CFR 177 Materials

- The FDA lists approved polymers for equipment in contact with food production or products

- Tapflo Gulf’s materials comply with FDA §21 CFR 177, ensuring they are safe for use in food-related applications

EN 10204 Material Traceability

- EN 10204 provides material traceability for equipment

- EN 10204:2.1 indicates compliance with material specifications, while EN 10204:3.1 provides a detailed traceable record, particularly for metals in contact with the medium

EC 1935/2004 Regulation

- This European Regulation applies to all food contact materials (metals, plastics and rubbers) to ensure they are safe for use with food products

- Materials must be marked with the glass and fork symbol and be traceable throughout the production chain, as per EN 10204

CE Conformance

- The CE mark signifies compliance with the essential health and safety requirements of EC Machinery Directive 2004/42/EEC, ensuring product safety

ATEX Directive 94/9/EC

- Equipment approved for safe area operation within potentially explosive atmospheres is categorised based on suitability for specific zones

- Tapflo Gulf’s pumps conform to ATEX Directive 94/9/EC to ensure safety in these environments

3-A Compliance

- 3-A Sanitary Standards, specific to the United States, enhance food safety through hygienic equipment design

- 3-A compliance ensures food product contact surfaces can be cleaned using CIP/SIP procedures and allows for easy dismantling for manual cleaning or inspection

Conclusion

At Tapflo Gulf, we understand the critical importance of adhering to these rigorous standards and certifications. Our commitment to USP VI materials, EHEDG certification and compliance with various regulations ensures that our process pumps are not only efficient but also safe for use in a wide range of applications. When you choose Tapflo Gulf, you’re choosing quality, safety and peace of mind.